ADDITIVE MANUFACTURING

THE DESIGN, PRODUCTION, AND QUALITY CONTROLS

NOVEMBER 2024 COURSE

INVEST IN YOUR PROFESSIONAL DEVELOPMENT

BY LEARNING ADDITIVE MANUFACTURING!

You’ve been debating

on wether or not

to take the leap.

Now’s the time!

Join Travis Davis, a former NASA engineer, as he takes you through an 8-week Designing for Additive Manufacturing Course.

Additive Manufacturing, also known as 3D Printing, is an emerging trend in the manufacturing sector. It has applications in Prototyping, Product Development, Aerospace, Medical Devices, Tissue Engineering, and more. The global additive manufacturing market is predicted to be 36.61 billion USD by 2027.

Unlock a world of possibilities with Additive Manufacturing. It can accelerate product development, offer customized products and implants, increase production flexibility, reduce tooling investments, and enable co-creation. Imagine the potential for your business and the innovative solutions you can create in your field. The possibilities are truly limitless!

Learn How You Can Apply Additive Manufacturing in Your Day-to-Day Applications!

COURSE OUTCOMES

1. Acquire the vocabulary necessary to navigate the complex, multivariate landscape of additive manufacturing equipment, materials, and applications.

2. Understand the fundamental principles and workflow for AM of polymers, resins, and metals and how these principles govern the performance and limitations of each mainstream AM process.

3. Learn to identify how, when, and where AM can create value across the entire product lifecycle, from design concepts to end-of-life, and how to select an AM process and material for a specific application.

4. Acquire the skills necessary to design parts for AM that combine engineering intuition with computationally driven design and process-specific constraints.

5. Assess the value of an additively manufactured part based on its production cost and performance.

6. Evaluate the business case for transitioning a product to be made using AM versus the conventional approach, either in part or in whole.

7. Develop a cutting-edge perspective on digital transformation and the factory of the future.

We Believe in Making Your Imagination Come to Life

Through Additive Manufacturing.

Additive Manufacturing has found one of its most innovative + versatile applications in the fields of

MEDICINE + HEALTHCARE

.

Additive Manufacturing Applications

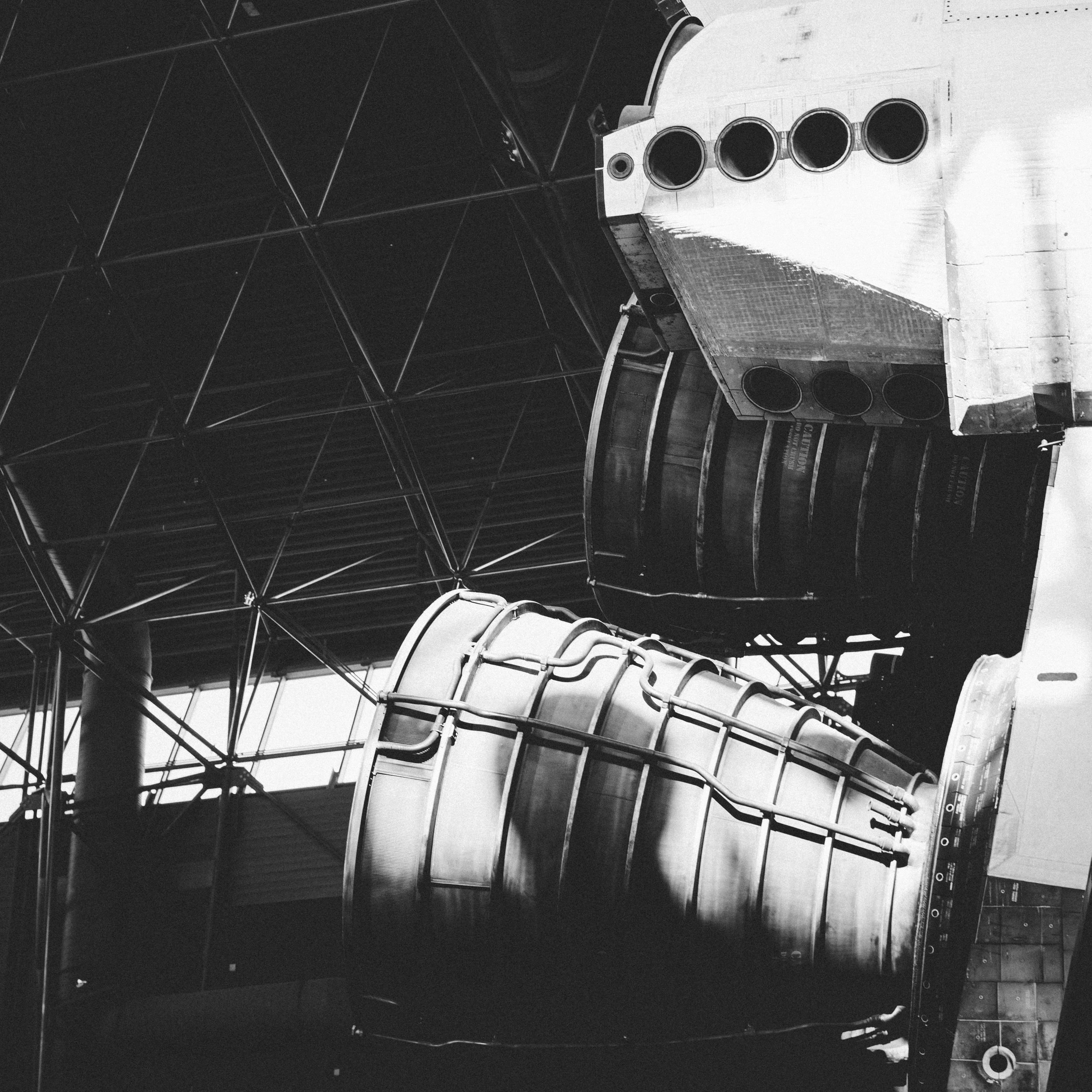

Aerospace

✔︎ Liquid Propulsion Components

✔︎ AI Defined Structures

✔︎ Unmanned Aerial Vehicles

Medical

✔︎ Dental

✔︎ Orthopaedic Technology

✔︎ Tissue Engineering

Industry

✔︎ PreProduction Tooling

✔︎ Handling & Robotics

✔︎ Guards & Jigs

Lifestyle

✔︎ Jewlery & Watches

✔︎ Footware & Clothing

✔︎ Sports Equipment

Automotive

✔︎ Engine Development

✔︎ Engine Components

Tooling

✔︎ Injection Moulding

✔︎ Die-Casting

✔︎ Tool Repair

Rapid Prototyping

Academia

The Global Additive Manufacturing

Market Size is projected to be

$36.61 BILLION

By 2027

All The Tools You Need To

Launch YOUR CAREER

THE 3D PRINTING INDUSTRIAL REVOLUTION IS HERE.

LET US HELP YOU PREPARE!

Why YOU Should Use Additive Manufacturing

✔︎ Accelerates Product

Development

✔︎ Offerers Customized

Products

✔︎ Reduces Tooling Investments

✔︎ Increases Production

Flexibility

✔︎ Enables Mass Production

of “Un-Manufacturable”

Geometries

7 Categories of

Additive Manufacturing

Free Download

It includes the different categories of additive manufacturing and how to apply each.

Travis is a NASA Award-Winning Liquid Propulsion Design and Test Engineer who Holds Multiple Patents including NASA Patents in the Additive Manufacturing Field.

Meet Your Instructor

Travis began his professional career as a wildland firefighter team lead in the Rocky Mountains of Montana. He holds a Bachelor of Science degree in Mechanical Engineering with 6+ years of experience at NASA’s Marshall Space Flight Center as an award-winning Liquid Propulsion Design and Test Engineer. He specialized in utilizing metal, polymer and resin additive manufacturing while at NASA and holds NASA patents in that field. After being chosen as a George J. Mitchell Scholar, he earned a Master of Science degree in Biomedical Engineering from Trinity College Dublin, with a focus on Medical Device Design and earned his Private Pilot license during his time at NASA.

NOVEMBER 2024 ENROLLMENT IS NOW OPEN!

Learners who successfully complete the course will receive a Digital Certificate showing completion of the Design for Additive Manufacturing Course.

Certificate Of Completion

ONE-TIME PAYMENT

ONE PAYMENT OF $2,499 $1,997

PAYMENT PLAN

THREE PAYMENTS OF $999 $699

8-WEEK COURSE OUTLINE

Introduction

➾ The vocabulary and status of AM and its implications.

➾ A description of the AM workflow and digital thread.

➾ First-Hand experience of industry leaders utilizing AM Benefits

➾ An overview of all major AM processes and comparison of their performance.

➾ Modules on the fundamentals, materials, and design guidelines for each process.

Additive Manufacturing Processes

Applications of Additive Manufacturing

➾ A structured presentation of AM across the product lifecycle.

➾ AM application examples from aerospace, automotive, medical, and more.

➾ A methodology for selecting and classifying potential applications of AM.

Designing for Additive Manufacturing

➾ Engineering approaches to design for AM, spanning processes and materials.

➾ Design methods for novel geometries, lattices, and infill patterns.

Designing for Additive Manufacturing

➾ Software for build preparation, generative design, and part/process simulation.

Designing for Additive Manufacturing

➾ Process and materials selection, assessment of performance, quality, and cost tradeoffs.

Cost + Value Analysis

➾ Understand how to quantitatively capture the value of AM versus conventional manufacturing.

➾ Implications of AM on supply chain operations.

The Future of Additive Manufacturing

➾ Assess critical technologies that will complement AM in the future, including robotics, advanced materials, and computation.